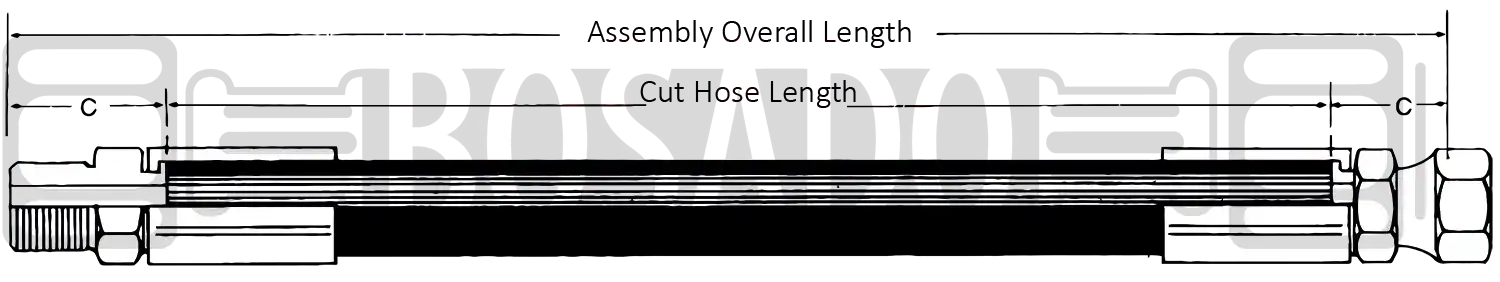

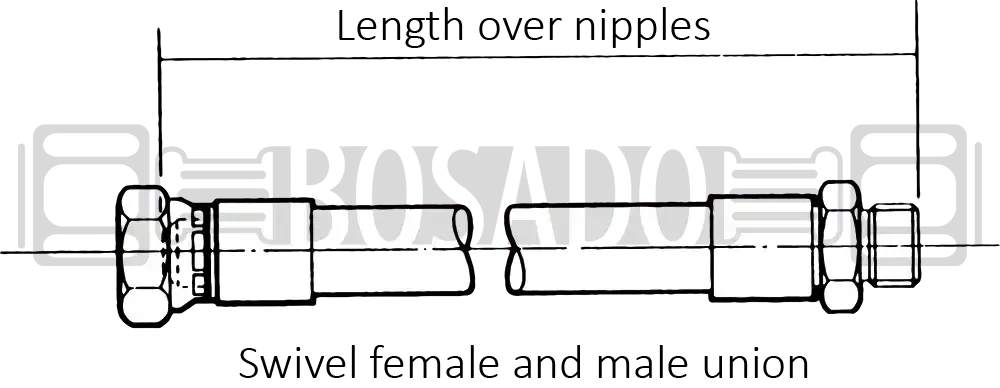

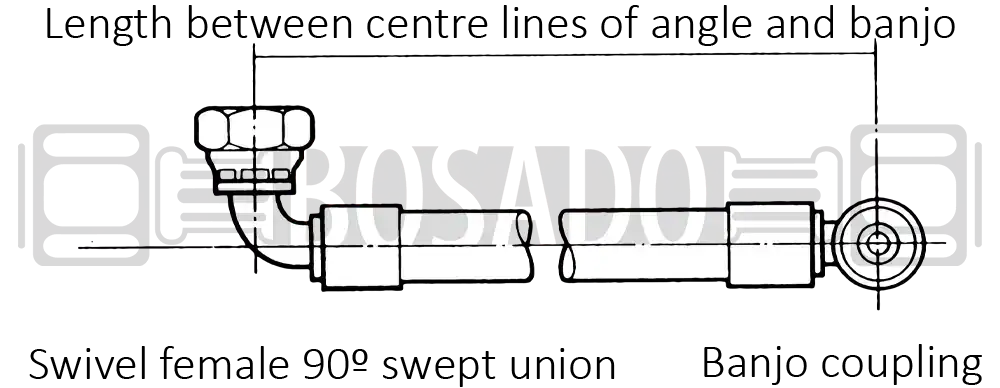

For most assemblies, the correct assembly length may be determined by direct measurement of the equipment or a drawing. Minimum bend radii as shown in the hose specification tables should be observed.

Remember that hydraulic hose under pressure will elongate up to 2% of its length or contract up to 4% depending on pressure, type and size. Sufficient allowance should be made to permit such changes in length.

Español

Español Français

Français